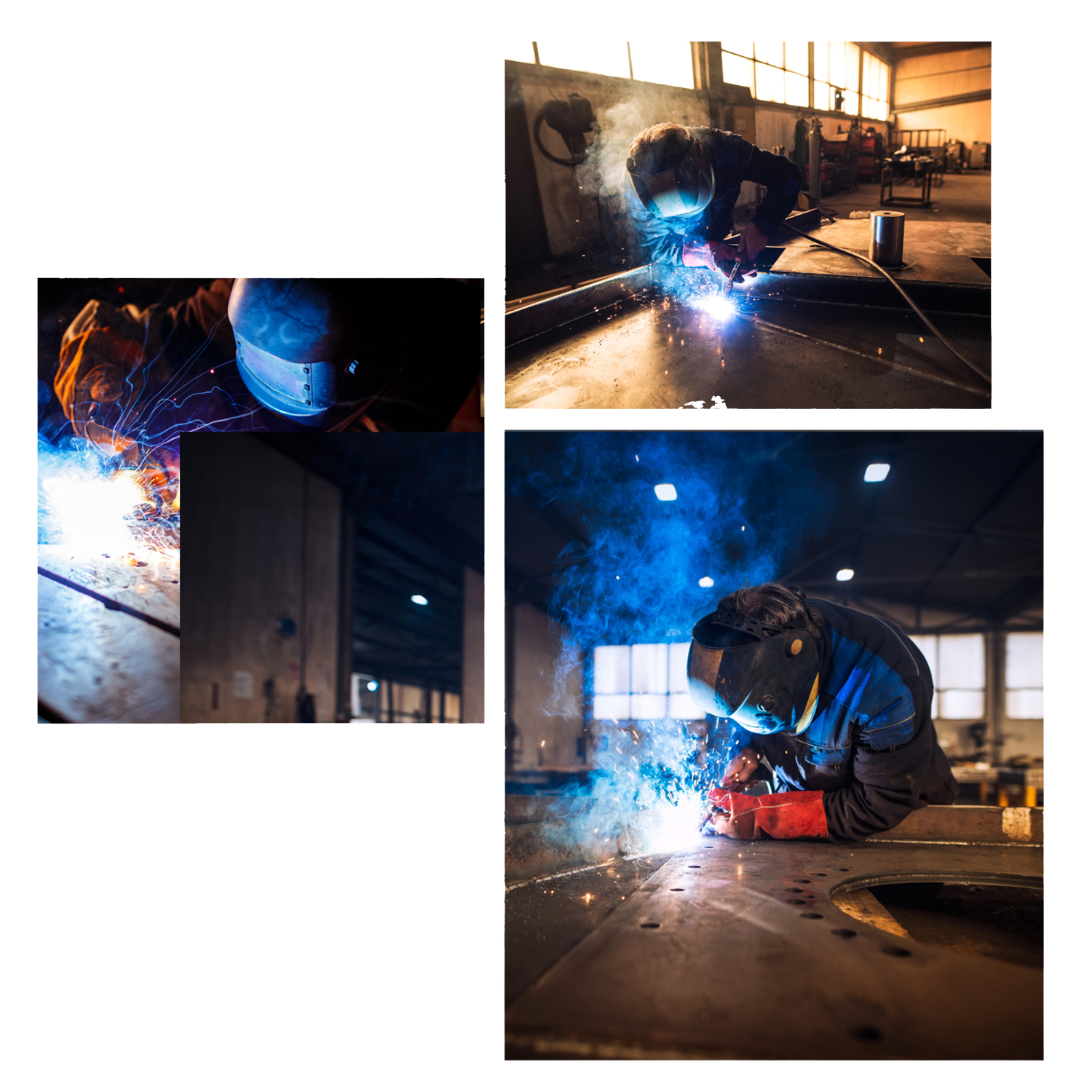

WELDING

TIG Welding

TIG welding offers exceptional control over heat input for welding a wide range of metals, including stainless steel, aluminum, titanium, and copper alloys. Its ability to produce high-quality welds with minimal distortion makes it suitable for applications requiring precise and aesthetically pleasing welds, such as intricate fabrications and automotive parts.

At MetalTek, our TIG welding service offers unparalleled precision and craftsmanship for various metalworking applications. Our skilled technicians utilize state-of-the-art TIG welding equipment and techniques to deliver clean, high-quality welds that meet the most exacting standards. Whether joining thin materials, welding exotic metals, or creating intricate welds with minimal distortion, our TIG welding service can handle a wide range of projects with precision and efficiency. With a commitment to quality and attention to detail, MetalTek ensures that every TIG weld meets the highest durability, strength, and aesthetics standards.

MIG Welding

Stick Welding

MetalTek’s stick welding service offers reliable and robust solutions for various metalworking needs. Stick welding is popular for outdoor projects and adverse weather conditions due to its simplicity, portability, and ability to weld thick, dirty, or rusty surfaces.

Our skilled welders are proficient in shielded metal arc welding (SMAW) techniques and use top-quality stick welding equipment and electrodes to deliver strong and durable welds in challenging environments. Whether repairing heavy equipment, fabricating structural components, or performing maintenance on industrial machinery, MetalTek’s stick welding service ensures high-quality welds with excellent penetration and fusion. With a focus on safety, efficiency, and quality craftsmanship, MetalTek provides exceptional stick welding services that meet the needs of our clients and exceed their expectations.

Hardfacing

MetalTek’s hardfacing service offers comprehensive solutions for protecting and enhancing the performance of metal components in demanding environments. Our skilled technicians use advanced hardfacing techniques and high-quality hardfacing materials to increase surface hardness and resistance to wear and corrosion. Effectively hardfacing vulnerable areas of metal components can extend their service life, reducing downtime, maintenance costs, and the need for frequent replacements.

Whether protecting equipment from abrasive wear, extending the lifespan of machinery, or enhancing the durability of industrial components in high-wear applications, MetalTek’s hard-facing service provides reliability. With a commitment to quality craftsmanship and customer satisfaction, we ensure every hardfaced component meets the highest durability, performance, and longevity standards. Protect your equipment in harsh operating conditions with MetalTek’s hardfacing.